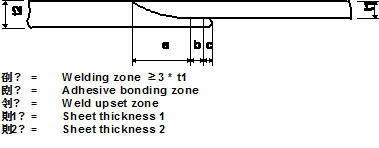

Metal sheets having differentthicknesses are welded together using themashresistance welding method- eg in the automotive industry - for thepurpose of weight saving. These sheets are further processed by forming (deepdrawing) them to manufacture car body parts. In order to ensure the deepdrawing quality, the width of the welding zone ?a“ (3 3 * t1) must be checkedfor any lack of fusion.

用滾壓電阻縫焊法把不同厚度的金屬板焊接在一起,例如:汽車制造業為了減輕重量,這些板材被進一步加工成汽車的車體部位,為了確保深沖壓的質量,焊縫寬度區域的任何未熔合都不允許存在。

SOLUTION:

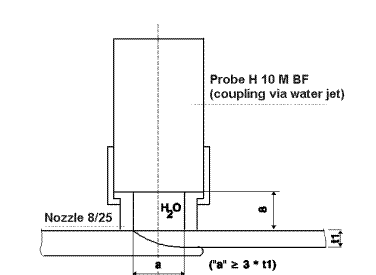

The waterflow probe H 10 MBF, equipped with an 8 mm long nozzle, is guided along the weld - as shownin the figure. The sound beam covers the complete welding zone with asensitivity loss of 6 dB at the twoweld edges.

如圖所示,H 10 M BF水柱探頭帶有8mm的噴嘴,聲束覆蓋整個焊縫區域,以在兩塊薄板結合處邊緣底波下降6DB作為靈敏度。

xis-Ber / Seite 2

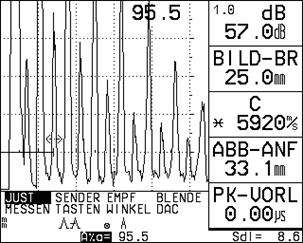

A too narrow weld and any lack offusion are indicated by a series of intermediate echoes within the echosequence from the total thickness of the two welded sheets.

窄焊縫中的任何未熔合通過在兩塊薄板結合處低波之間出現的一系列中間回波被顯示出來。

Defective weld

缺陷焊縫

The amplitude height of the flaw

indication corresponds to a

? 1.0 mm flat-bottom hole.

缺陷的幅度顯示和? 1.0 mm的平底孔相當

Flaw-free weld

無缺陷的焊縫

SUITABLE EQUIPMENT:

設備

Ultrasonic instrument: 超聲設備USD15, USIP 20

Probe: 探頭 H10 M BF (67 322)

Nozzle: 噴水嘴 8/25 (67 321)

Cable: 探頭線 PKP2 (66 709)

The nozzle 8/25 was developed for thesheet combination 2 mm (t1) and 3 mm (t2).

8/25噴嘴用于板厚2 mm (t1) and 3 mm (t2)焊接的檢驗